Additive Manufacturing

For design agility, industry responsiveness and manufacturing flexibility

Our Process

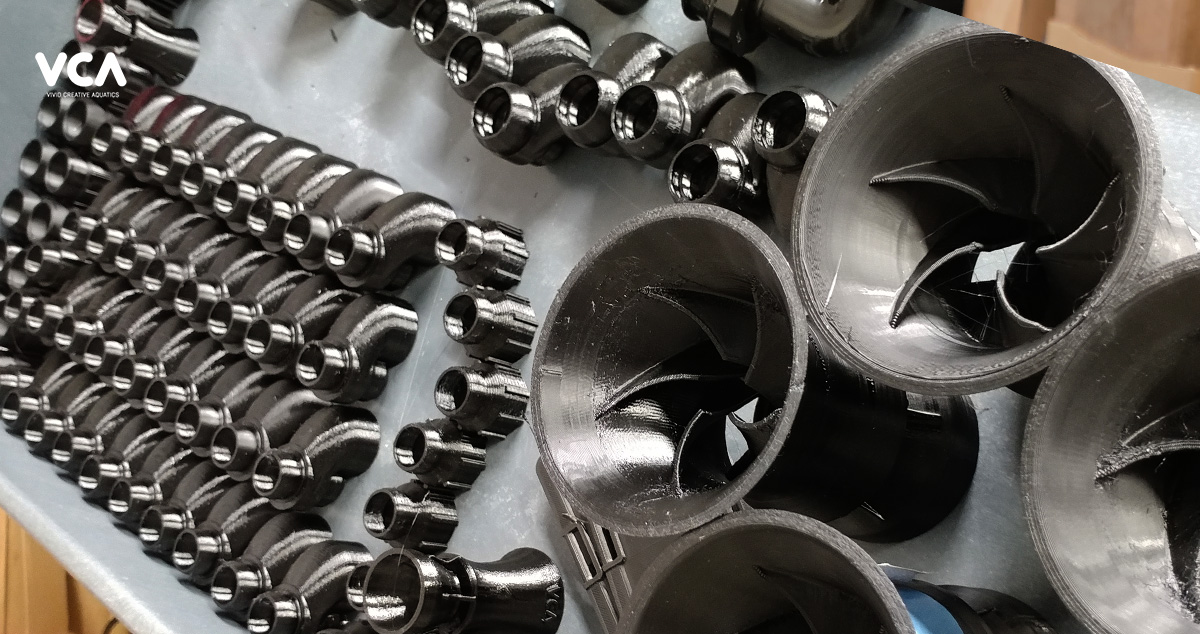

The dedicated VCA team performs all post-processing and QC inspections in-house to ensure the that every product we produce is up to the quality control standards that we have set.

Each part is put through our 4-stage Quality Control system where it is: inspected, sized, brushed and tweezed and then heat treated before final approval. Each product is then test fit again, before being assembled into one of our Flow Kits or placed in its retail packaging.

We take great pride in the quality of our products and stand behind them 100%.

Hilary Jaffee( Waterlogged1313) visited the Vivid Creative Aqautics facility for a tour.

Why Additive Manufacturing?

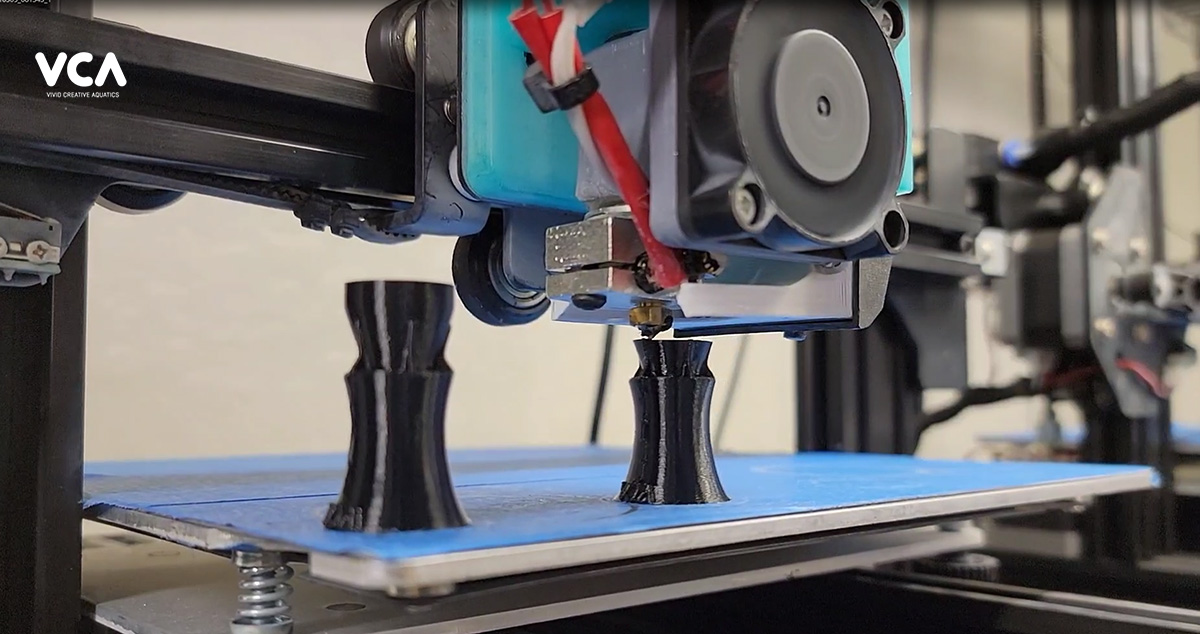

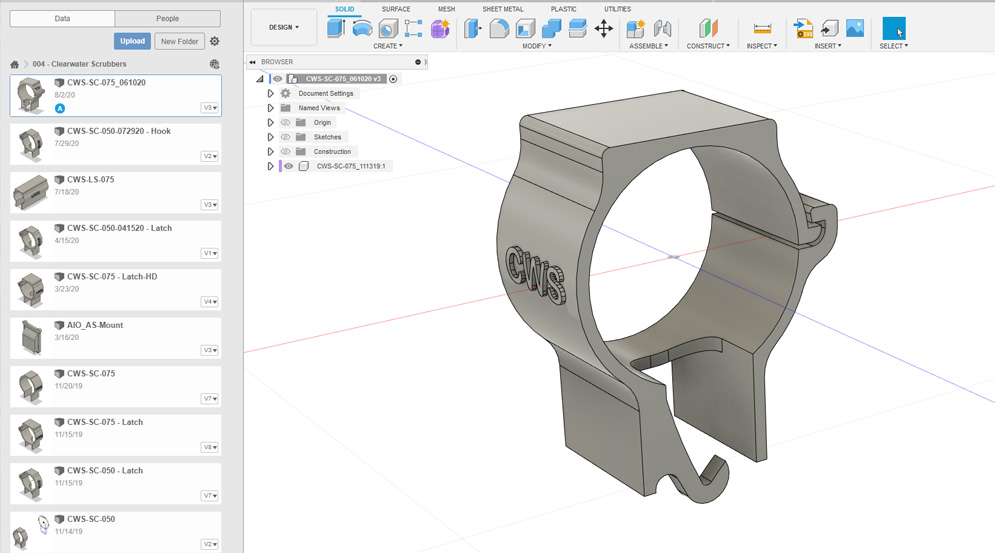

At Vivid Creative Aquatics, we utilize additive manufacturing techniques to produce most of our product line. Additive manufacturing allows us to produce the Random Flow Generator®. The patented internal design of the Random Flow Generator does not lend itself to more traditional manufacturing techniques such as injection molding. This is due to the internal shape of the RFG and the limitations of injection molding. As a result, the only effective way to make the Random Flow Generator is through additive manufacturing ,which we’ve embraced in all of our processes.

The Patented Radom Flow Generator®

What are the other advantages of Additive Manufacturing?

In addition to producing the Random Flow Generator, we also utilize additive manufacturing to produce a wide range of adapters and fittings. This allows us to respond quickly to industry changes and product changes by the various aquarium brands. Because we are not locked into specific designs due to the higher cost and longer lead times associated with more traditional manufacturing techniques, we are able to move quickly to make changes as they arise.

What Kinds of Materials Are Used?

We use a variety of materials based in the intended end-use of the products we manufacture. For most of our products that are intended for extended periods of use in the aquarium, we will use quality 3D printing filaments made from TPU (thermoplastic polyurethane) and PETG (Polyethylene terephthalate glycol-modified).Both materials are industrial thermoplastic 3D printing filaments with excellent chemical resistance. PETG is strong semi flexible material with good impact resistance. TPU has excellent flexibility and provides extreme durability making it ideal for the Random Flow Generator®

For other products and accessories such as brackets and mounts, we may use PLA+ (Polylactic acid).

Design and Manufacturing Services

We also offer product design and consultation for the additive manufacturing process as well as additive manufacturing services. Our facility has the capacity to handle production runs as small as a few custom parts to as many as a 1,000 parts in a single production run.